Vibrating Feeder

Leading Vibrating Feeder Manufacturer, Supplier, and Exporter in India

Mitool India is a prominent Vibrating Feeder Manufacturer, Supplier, and Exporterbased in Ambarnath MIDC, Thane, Maharashtra. Our advanced range of Electromagnetic Vibrating Feeders and Electromechanical Vibrating Feedersis designed to handle bulk material transportation efficiently across multiple industries, ensuring seamless operation and increased productivity.

What is a Vibrating Feeder?

A Vibrating Feeder is a highly efficient material handling system that transports bulk materials using controlled vibrations. These feeders are widely utilized in industries such as mining, pharmaceuticals, food processing, and construction to facilitate smooth material movement with minimal manual intervention. The vibratory motion ensures precise and uniform material flow, reducing operational downtime and enhancing efficiency.

Types of Vibrating Feeders

Electromagnetic Vibrating Feeders

Electromagnetic Vibrating Feeders operate using electromagnetism, providing controlled and consistent material flow. These feeders are particularly beneficial for handling fine and granular materials with precision.

• Key Features:

• High Precision Control: Adjustable feed rate ensures accurate dosing of bulk materials.

• Low Maintenance: No moving parts reduce wear and tear, minimizing downtime.

• Energy Efficiency: Consumes less power, making it an economical choice.

• Versatile Applications:Ideal for food processing, pharmaceuticals, chemicals, recycling, and more.

Electromechanical Vibrating Feeders

Electromechanical Vibrating Feeders use mechanical and electrical components to generate powerful vibrations, making them suitable for handling heavy-duty materials.

Key Features:

• Rugged Construction:Built for harsh industrial environments, including mining and construction.

• High Material Handling Capacity:Capable of managing large volumes efficiently.

• Adjustable Feed Rates:Customizable vibration intensity to suit material characteristics.

• Low Noise Operation:Reduces operational noise levels for a better working environment.

Why Choose Mitool India for Vibrating Feeders?

Mitool India is a trusted name in the industry, offering high-performance Vibrating Feeders tailored to diverse industry requirements.

• Advantages of Choosing Us:

• Custom Solutions:We provide tailor-made vibrating feeder solutions based on industry needs.

• Premium Quality Assurance:Manufactured using high-grade materials for durability and longevity.

• Expert Engineering Team:Our experienced engineers ensure the latest technological advancements in every product.

Reliable Customer Support:We offer comprehensive after-sales support and service.

Competitive Pricing:Cost-effective solutions without compromising on quality.

Applications of Vibrating Feeders

Our Vibrating Feedersserve multiple industries, ensuring efficient material handling processes:

• Cement Industry– Transporting raw materials like limestone, clay, and gypsum for processing.

• Power Plants– Feeding coal and solid fuels into furnaces and boilers.

• Construction Industry– Handling sand, gravel, and crushed stones efficiently.

• Foundry Industry– Assisting in metal, sand, and binder transportation for casting processes.

• FMCG Industry– Ensuring smooth transfer of ingredients and finished goods in production lines.

Plastic Industry– Managing the movement of plastic resins, additives, and recycled materials.

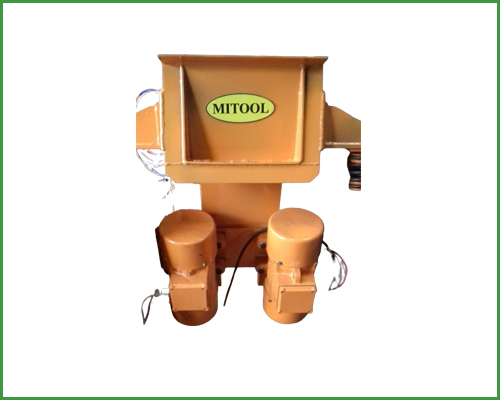

Vibratory Motors for Vibrating Feeders

Our Vibratory Motorsare fully enclosed three-phase, squirrel cage induction motors equipped with adjustable eccentric weights mounted on the extended shaft. These motors generate controlled vibrations that ensure smooth and consistent material flow.

Key Features:

• Heavy-Duty Shaft Design– Withstands high radial loads.

• Parallel Mounted Motors– Ensures linear vibrations for bulk material movement.

• Clockwise & Counterclockwise Rotation– Ensures optimal performance in large feeders.

Construction & Mounting Options

We offer multiple Vibrating Feederconfigurations:

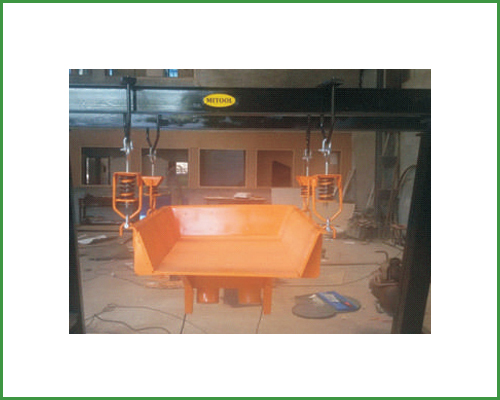

• Base Mounting– Sturdy and stable installation for heavy-duty applications.

• Suspension Mounting– Ideal for space-constrained environments.

Tubular Vibratory Feeders

Mitool India provides Tubular Vibratory Feedersdesigned for enclosed material handling, preventing contamination and ensuring smooth material transfer.

Specifications:

• Available in round and square sections

• Diameter options: 160mm to 500mm

• Length options: 1m to 5m

• Drive: Vibratory motors or electromagnetic units

• Adjustable angles: 10° uphill to 15° downhill (motorized models)

Working Principle of Vibrating Feeders

Our Tubular Vibrating Feedersoperate based on the principle of controlled inertial vibrations. The simple yet effective design ensures:

• Efficient transport of materials with minimal spillage

• Smooth intermediate transportation of granular and powder materials

• Suitability for diverse industrial environments

Contact Us

If you are looking for a reliable Vibrating Feeder Manufacturer, Supplier, or Exporter in India, Mitool India is your trusted partner. Contact us today to discuss your requirements and get customized solutions tailored to your business needs.

Website: www.mitoolindia.com

Mitool India – Enhancing Efficiency with Advanced Vibrating Feeder Technology!

Mitool Heavy-Duty Vibro Motor Powered electromechanical Vibrating feeders are high frequency vibrating machine of heavy duty capable of conveying bulk material from storage to processing or between processed at a continuous controlled rate flow.

Mitool Electromechanical Vibrating feeders are used in processing industries for handling all type of materials such as hot, damp, lumps, dusty or abrasive for various functions like flow of material from storage, proportioning and blending, packaging,mixing, weighing, sprinkling, screening, scalping, crushing, washing, drying, heating,cooling, dusting, spreading, batching and etc.